® Rittagraf

Welcome to our guide on printing large custom stamps! If you've ever wondered how to print your own custom large stamp, you're in the right place. Large rubber stamps are incredibly practical tools for personalizing packaging, bags, stationery, and even textiles.

We provide tips and various options to make the most of your projects with large and big rubber stamps. Keep reading to find the option that best suits your needs!

Multiple Applications for Large Stamps

A large stamp has countless applications. Whether you're marking boxes, printing paper bags, personalizing cardboard packaging, or stamping t-shirts and fabrics like tote bags, we present various ways to apply ink and achieve professional results. Explore the advantages and disadvantages of each printing option to find the one that best suits your needs.

Below, we offer different options for applying ink and stamping a large stamp, as well as the advantages and disadvantages of each system or procedure.

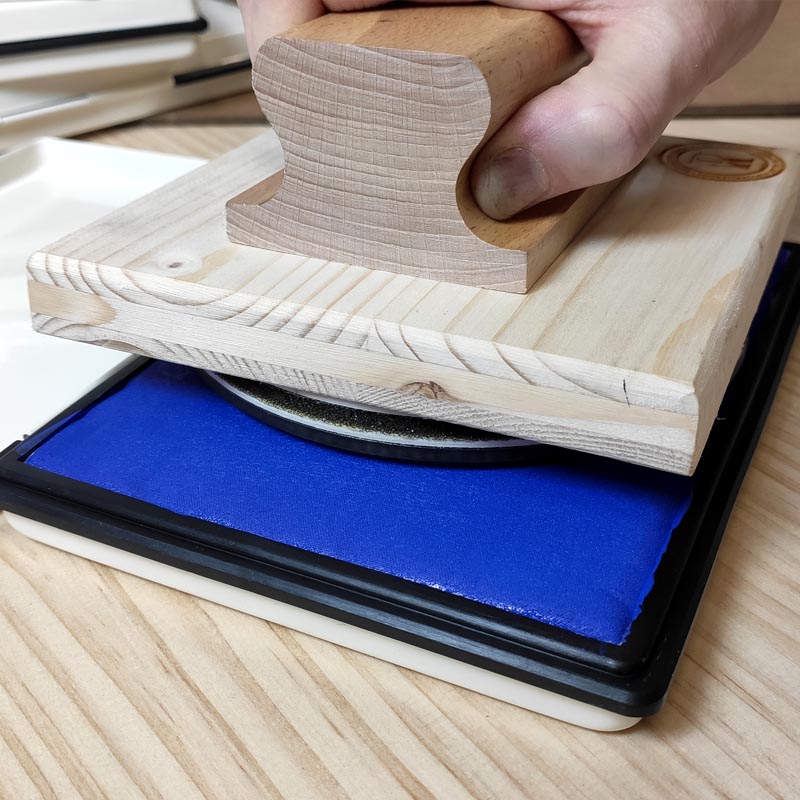

Option 1: Stamping a Large Stamp Using a Big Ink Pad and Ink Refill

This is a very convenient and elegant option. There are professional big ink pads with metal lids that measure up to 20x30 cm. These pads come uninked (virgin) and are made with muslin fabric, which helps distribute the ink evenly. These pads can be filled with any liquid stamp ink. While any type of stamp ink can be used, the quality of the ink will affect the quality of the stamp's reproduction. Economical options like Coloris inks refills (250 ml) are available, but they are of lower quality compared to Versacraft inks, which are ideal for printing on various surfaces.

Advantages:

- The format of the ink pad allows for inking stamps of various sizes.

- There is a much wider variety of colors available in small formats like Versacraft stamp ink refills.

- High-quality ink refills, such as those from Versacraft, come in a wide variety of colors.

- The Versacraft ink series is indelible and suitable for printing on textiles, wood, plaster, plastic, and more.

Disadvantages:

- Ink needs to be manually applied to the pad.

- A drying time of 1 to 2 minutes is required.

- High-quality inks come in relatively small containers (20 to 30 ml). One refill can fill a large pad, but more refills will be needed for larger formats. This can be a consideration if frequent use is anticipated.

- Each ink pad can only be used for one color. To use different colors, you will need different pads, each loaded with a different color.

Using Versacraft Ink refill to charge a Large Stamp Pad

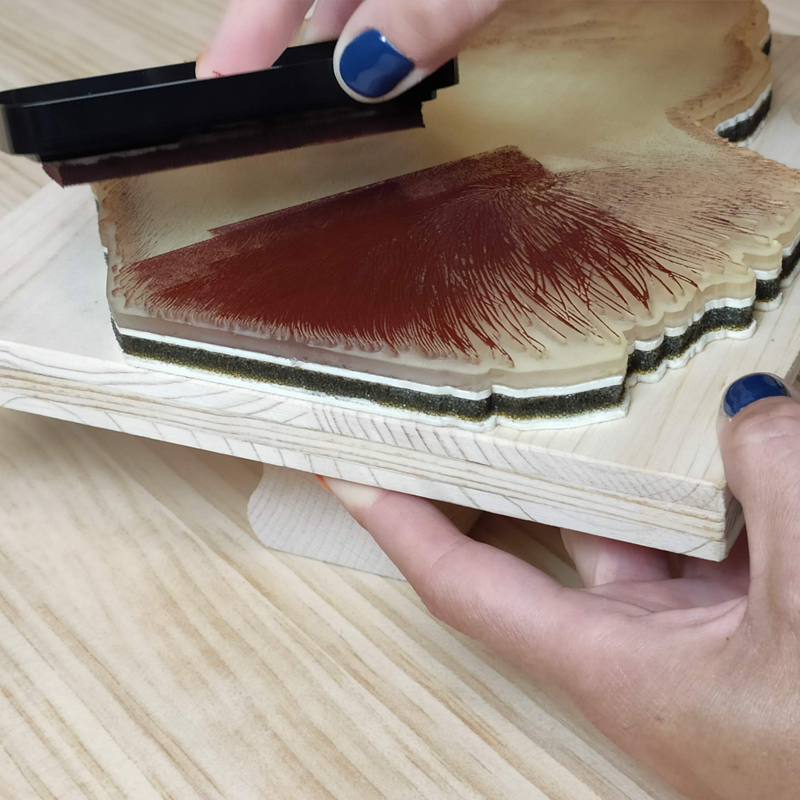

Option 2: Stamping a Large Stamp Using a Small Ink Pad Already Loaded with Ink

This option involves using rubber stamp inks that already contain ink. There is a wide variety of ink series available, such as Versacraft inks, Versafine inks, Memento inks, Memento Luxe inks, among others. Each ink series for stamps has a different application and color chart. These inks are a great option when production is not expected to be very long. Some stamp inks have a raised pad, which allows for applying ink to much larger surfaces. Simply tap the ink onto the rubber stamp surface until it is fully covered.

Advantages:

- This option is much more economical than the previous one.

- Allows working with more than one color without making a significant investment.

- Provides more control over the amount of ink applied, resulting in better ink coverage.

- Variety of stamp ink types for different surfaces: textile inks, inks for plastics, inks for non-porous surfaces, even metal inks or complex surfaces.

Disadvantages:

- The size of the ink pad means it takes longer to apply the ink, although it's quicker and more convenient than it seems.

- Some series of stamp inks do not offer refills, so a new pad will need to be purchased when the ink runs out.

Printing a Large Stamp with Versafine Clair Stamp Ink by Tsukineko

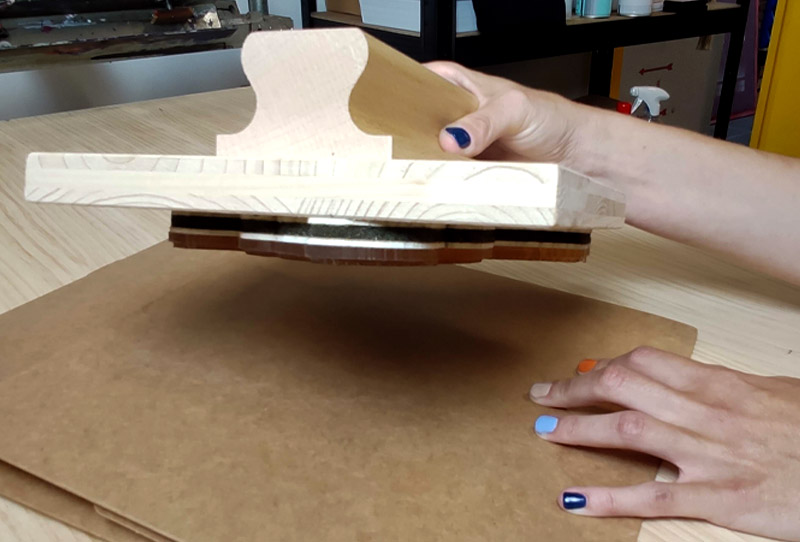

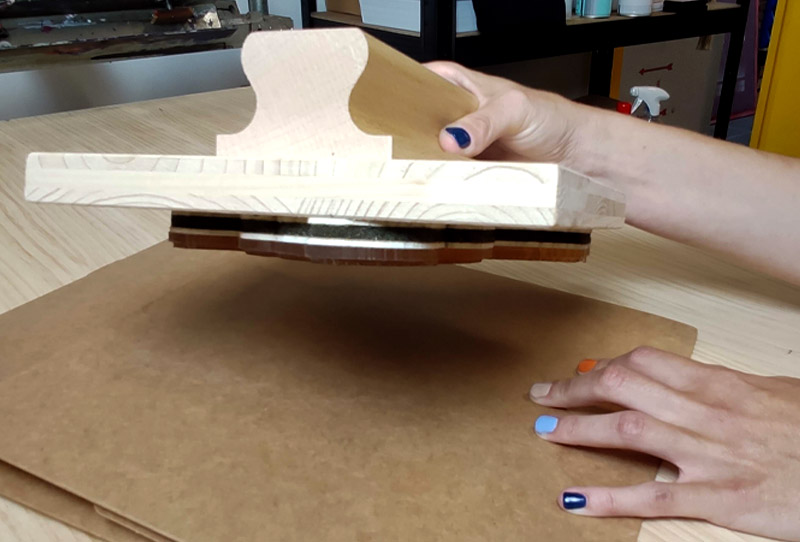

Option 3: Stamping a Large Stamp Using Engraving Ink Applied with a Roller

A rubber roller allows us to apply ink to large surfaces very effectively. Simply create an ink field on a non-porous surface such as glass or marble, or a more manageable support like plastic or acetate. Spread the ink evenly with a roller until you achieve a homogeneous film, then apply the ink as if it were linoleum, synthetic plate like softcut, or woodcut.

Within this option, we can choose inks that are water-based or oil-based. For print this Big Stamps we have used offset ink (oil-based).

- Engraving Water-based inks: Dry faster on the stamped support and are easier to handle, especially when cleaning.

- Engraving Oil-based inks: Take much longer to dry (between 24 and 72 hours) depending on the surface and the amount of ink. Drying agents can be used to speed up the process. The finish is much shinier and more "professional." Cleaning can be done with vegetable oil cleaners. While cleaning is a bit more laborious, the finish is worth it.

Advantages:

- We control the ink layer and expand the options of ink types: traditional linoleum and engraving inks, woodcut inks, or offset inks.

- We can find a wide variety of colors and even create our own mixes.

- The printed finish is very professional.

Disadvantages:

- Requires larger infrastructure: a rubber roller and a non-porous surface to spread the ink.

- Drying time is much slower than stamp ink. Engraving oil inks or offset inks, for example, take 48-72 hours to dry, depending on the surface absorption and the type of ink.

- Utensils, roller, and ink field need to be cleaned afterward.

Option 4: Stamping a Large Stamp Using Textile Ink Applied with a Roller

If your intention is to print fabrics and textiles with large stamps, this may be the best option. Applying ink with a roller allows for direct control of the ink layer. When printing stamps on fabrics and other porous materials, it's advisable to load the rubber stamp with plenty of ink (something you can't do with a stamp pad).

Two very affordable ink options:

- Oil-based textile inks: There are special oil-based inks for relief printing, such as Speedball textile ink.

- Water-based textile inks: Water-based screen printing ink is highly recommended. It provides good coverage, behaves quite well on most stamps, and dries very quickly on the garment. For roller application, we recommend using our water-based textile lacquer ink.

With oil-based textile inks drying on the garment is much slower, up to 7 days! One advantage is that the roller and ink field also take a long time to dry. This allows for extended work periods without fear of the ink drying on the roller or rubber stamp.

Advantages:

- Allows for more generous ink loads. This is beneficial for printing on textiles, for example.

- Loading ink onto very large stamps is done more quickly with a stamp pad.

Disadvantages:

- Requires setting up a more complex infrastructure to spread the ink field. A non-porous surface and a rubber roller or foam roller are needed.

- Cleaning tools is more cumbersome.

If you choose this option, we recommend our tutorial on how to print large stamps on textiles using water-based screen printing inks.

Stamp Printing with Speedball Textile Engraving Ink

Stamp Printing with Rittagraf Screen Printing Textile Ink

Other Options for Printing a Large Stamp: Free Will!!

In applying ink to the large stamp, you're free to combine different types of inks and techniques. Regardless of whether they are water-based or oil-based or derived from petroleum, you can use any inks you can think of: woodcut inks, offset inks, flexographic inks, typographic inks, screen printing inks (especially water-based), and you can apply them in different ways: with rubber rollers, brushes, stencil sponges, and even create special inkwells with shapes and fabrics.

Experimentation demands risks but offers endless new sensations! Give it a try and you'll discover new realms of printing.

Now that you've seen the different options for inking a large rubber stamp, you're ready to choose the option that best suits your needs and your work.

If you have any questions, feel free to contact us, and we'll assist you with whatever you need. If you need a custom large stamp, don't forget to visit our website and explore all the options and possibilities we can offer. Alternatively, you can visit our store and workshop in Barcelona, where you can see examples and explore all kinds of options.

Order Your Large Stamps at Rittagraf

Our team specializes in manufacturing various types of rubber stamps, and we are pioneers in creating large stamps in Europe. Our designs have been imitated by a long list of competitors.

Our commitment to quality and innovation has led us to perfect our design and manufacturing processes. Today, we offer a wide variety of options for large stamps, from simple to complex designs.

On our website, you'll find a vast selection of custom large stamp designs and sizes. Additionally, our team of experts will be delighted to advise you at every step to help you find the perfect stamp for your needs.

Don't wait any longer to enhance your business image with a high-quality, personalized stamp. Contact us and discover why we are leaders in manufacturing large and custom stamps in Europe.

At Rittagraf, we are pioneers in large stamp manufacturing in Europe. Our wide range of options, from the simplest to the most complex designs, ensures that you'll find the perfect stamp for your needs. Enhance your business image with high-quality, custom big stamps. Contact us and discover why we are leaders in alrge and big stamp manufacturing in Europe!